Direct Lithium Extraction

Direct Lithium Extraction

DLE

Lithium is present in solution in varying amounts in a wide variety of geological environments.

These include salt lakes (salars and playas) found in high elevation deserts such as the Atacama in Chile, the Puna region of Argentina and the Qinghai region of China; in oil and gas well brines (produced waters); in geothermal brines, and in seawater.

Lithium is currently recovered from brine sources such as the salars in Chile and Argentina using solar evaporation to concentrate the brine by sequential precipitation of various sodium, potassium and sulphate salts to produce a high lithium content lithium chloride solution. This solution is then further purified by chemical precipitation and solvent extraction to remove residual magnesium, calcium, boron and other deleterious elements.

The purified lithium chloride is then reacted with sodium carbonate to precipitate lithium carbonate while the sodium chloride waste solution is discarded to ponds for evaporation to solid. The overall lithium recovery from solar evaporation processes is low, with lithium recoveries from the initial brine to final product rarely being more than 50% and often significantly lower.

Time frames for development of lithium carbonate plants based on solar evaporation can be extensive. Exploration, permitting and construction time frames of 5 – 7 years are typical. Typical evaporation times are at least 9 months and can be as much as 24 months and are subject to local environmental and weather conditions.

Evaporation cycles are also affected by the chemical composition of the brine, which impacts on the type and amount of reagents required during evaporation and purification process. DLE processes, on the other hand, are uninfluenced by environmental factors, have fast processing (hours to a few days at most to recover the lithium), and have high lithium recoveries in excess of 70% and often more than 90%.

The overall economics of solar evaporation processes are highly influenced by the initial lithium concentration in the brine. Due to the significant process losses, only salars with relatively high lithium brine concentrations (typically >500 mg/L) and low levels of interfering ions such as calcium, magnesium and sulphate can generally be considered for exploitation. Such brine resources are relatively scarce, especially within the context of favorable environmental, logistics and infrastructure conditions. Accordingly, processes that can treat low lithium grade brines to yield a high lithium concentration brine low in deleterious elements and suitable for further processing to final product are highly desirable. Such processes would enable development of substantially more of the known continental brine resources, especially in the western United States where continental brines typically have lithium concentrations <200 mg/L and are thus currently uneconomic to extract and process with conventional technology.

Unconventional lithium resources such as produced water from oil and gas operations and geothermal brines are receiving increased interest as potential sources of lithium. Such sources tend to be low grade, typically <200 mg/L, compared to lithium brines found in salars. However, they do offer potential advantages in terms of availability of both the resource and collection infrastructure and in terms of available energy (in the case of geothermal brines). In addition, development of such resources can offer environmental advantages related to disposal of spent brine. Treatment and disposal of produced water is a significant cost and environmental issue associated with oil and gas operations, especially hydraulic fracking in shale oil and gas production operations.

For all of these reasons, direct lithium extraction process technologies that can reduce or eliminate the necessity for solar evaporation, reduce the cycle time from initial brine recovery to final product, reduce reagent requirements, and can be applied to low grade and/or unconventional lithium sources such as oil and gas well produced waters and geothermal brines, can operate with high lithium yields and are environmentally friendly are under active development.

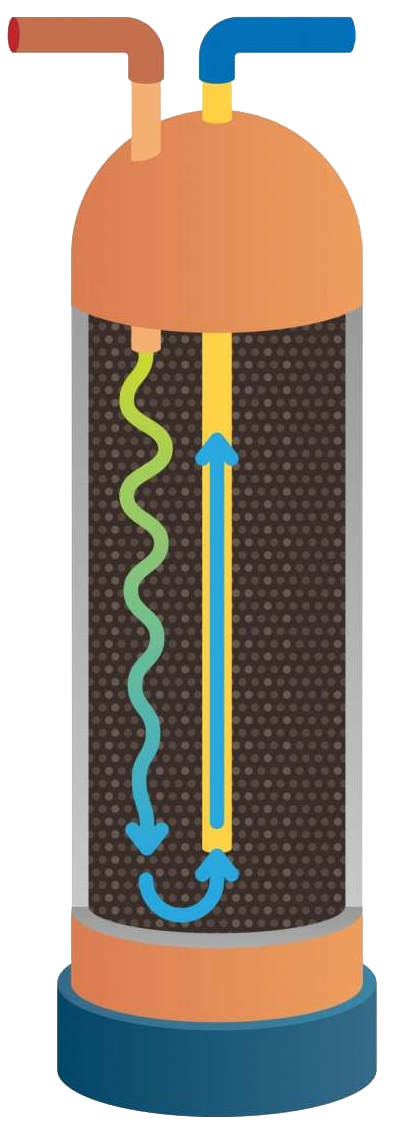

Direct lithium extraction refers to processes that can extract and/or purify low concentration lithium streams. The fundamental concept is that the lithium feed source is processed to selectively recover and concentrate/purify the lithium values without a significant change in the composition of the feed material save for removal of the lithium. There are five primary mechanisms for DLE:

Sorbent-based processes are considered the most versatile of the currently available DLE technologies. This is attributable to the following factors: